How to build a trap thrower: A step-by-step guide

Building your own trap thrower can be a rewarding project, allowing you to customize it to your specific needs and preferences.

This guide will walk you through the process, from gathering materials to final assembly.

Materials needed

- Base and Stand: Metal or wood

- Throwing Arm: Metal rod or aluminum strip

- Tension Spring: Heavy-duty

- Pivots and Bearings: For smooth operation

- Trigger Mechanism: Lever or electric switch

- Power Source: Motor (electric models) or manual crank

- Fasteners: Nuts, bolts, and screws

Step-by-step instructions

- Design the blueprint

- Sketch the design of your trap thrower, considering the dimensions and angles required for the throwing arm and base.

- Determine the power source and how it will integrate with the throwing mechanism.

- Build the Base

- Cut and assemble the base using metal or wood, ensuring it is stable and robust.

- Attach the stand to the base, providing a secure foundation for the throwing arm.

- Assemble the throwing arm

- Cut the metal rod or aluminum strip to the desired length for your throwing arm.

- Attach the tension spring to the base and the throwing arm. The spring should provide enough tension to launch the clay pigeon effectively.

- Install the pivots and bearings

- Attach pivots and bearings to the base and the throwing arm. These components will allow smooth movement of the throwing arm.

- Attach the trigger mechanism

- Install the trigger mechanism on the base. If using a manual lever, ensure it is easily accessible. For electric models, connect the trigger to the motor.

- Set up the power source

- For electric models, mount the motor on the base and connect it to the throwing arm. Ensure the motor is securely fastened and wired correctly.

- For manual models, attach a crank to the throwing arm to provide the necessary force for launching.

- Test the thrower

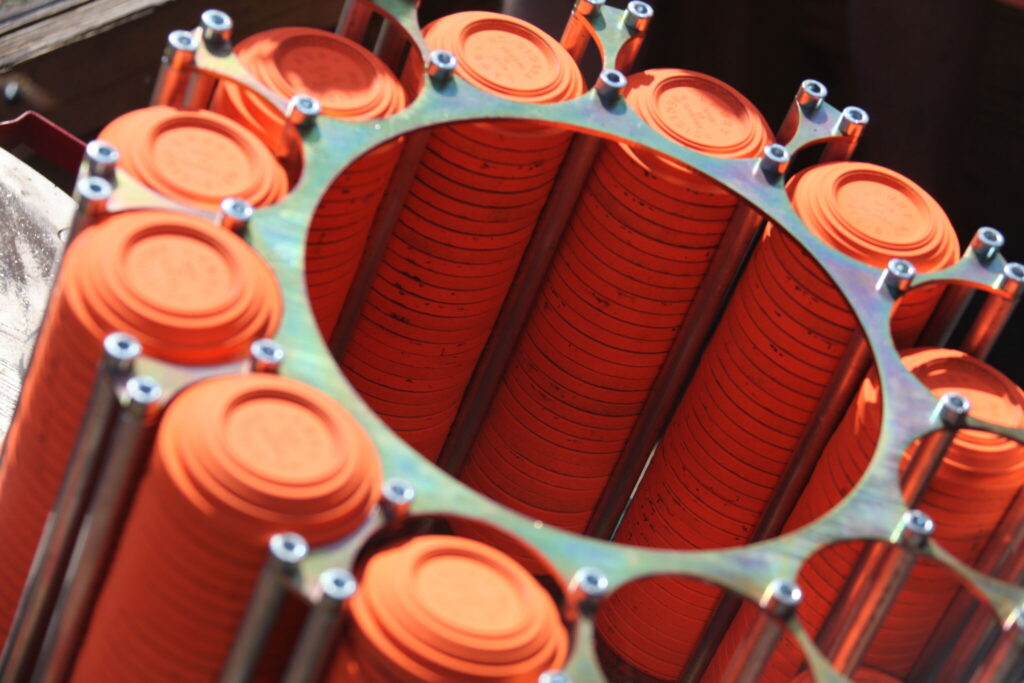

- Load a clay pigeon onto the throwing arm and test the mechanism.

- Make adjustments to the tension, angles, and trigger sensitivity as needed.

Tips for success

- Safety First: Wear protective gear and ensure all parts are securely fastened.

- Precision: Use precise measurements and high-quality materials to ensure reliable performance.

- Adjustability: Incorporate adjustable components to customize throwing angles and distances.

Conclusion

Building a trap thrower requires careful planning and craftsmanship. By following these steps and paying attention to detail, you can create a functional and reliable trap thrower tailored to your needs. For more tips and high-quality materials, visit Nordic Clays.

Happy building and shooting!